XTRA SHIELD™ is cured at 400 degrees Fahrenheit.

SAVE MONEY WITH CARBON STEEL COATING

CARBON STEEL COATED PIPE VS STAINLESS STEEL

Carbon Steel Coated

Stainless steel

We value our customers and their time. Our communication is top notch, and our pickups and deliveries are on time, so you’ll never be left waiting around. You can keep your business moving, because you’ll experience less downtime with our fast turnarounds.

Safety is a priority at North Basin, and we care about our people and your people. By keeping everyone safe, we prevent expensive delays. We hold our team and our facilities to the highest safety standards, and our safety record speaks for itself.

With North Basin, you know you’re getting a quality product. Our vigorous inspection includes wet sponge holiday detection mil thickness checks, cure testing and anchor profile testing. Our certified inspectors check every piece of pipe for the highest quality assurance.

Preventing corrosion is good for the planet and good for business. Our products are greener than traditional methods, avoiding air pollution and producing less waste. We’re committed to a clean planet and a clean work environment.

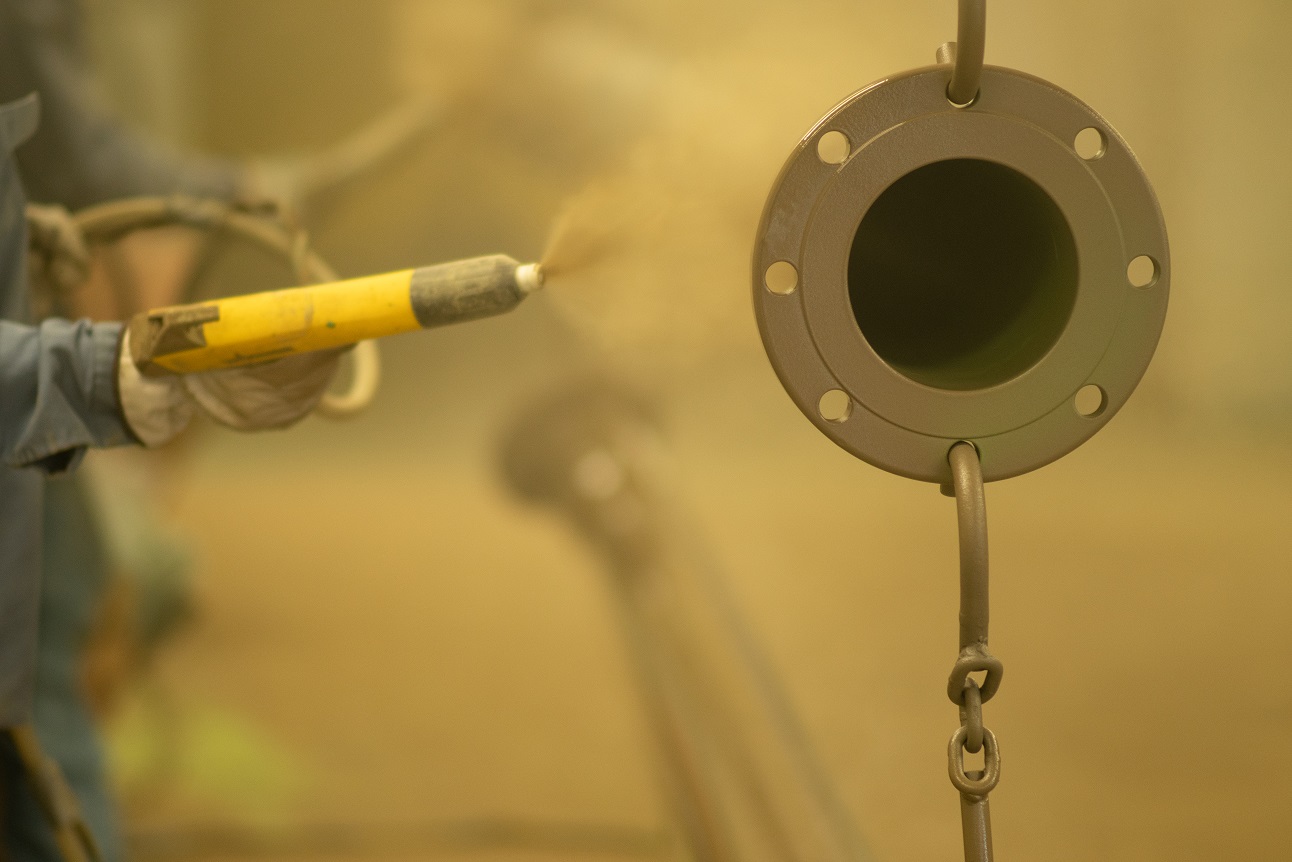

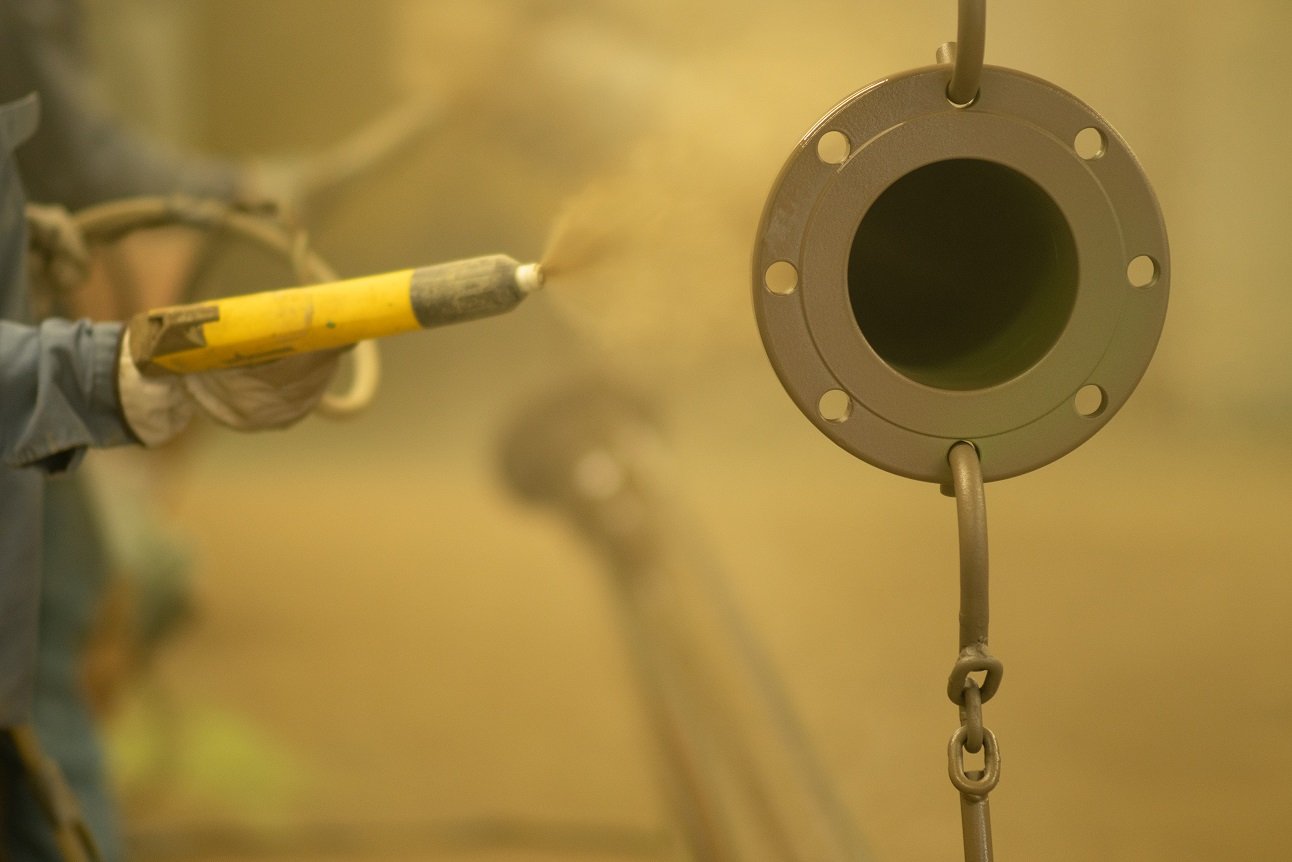

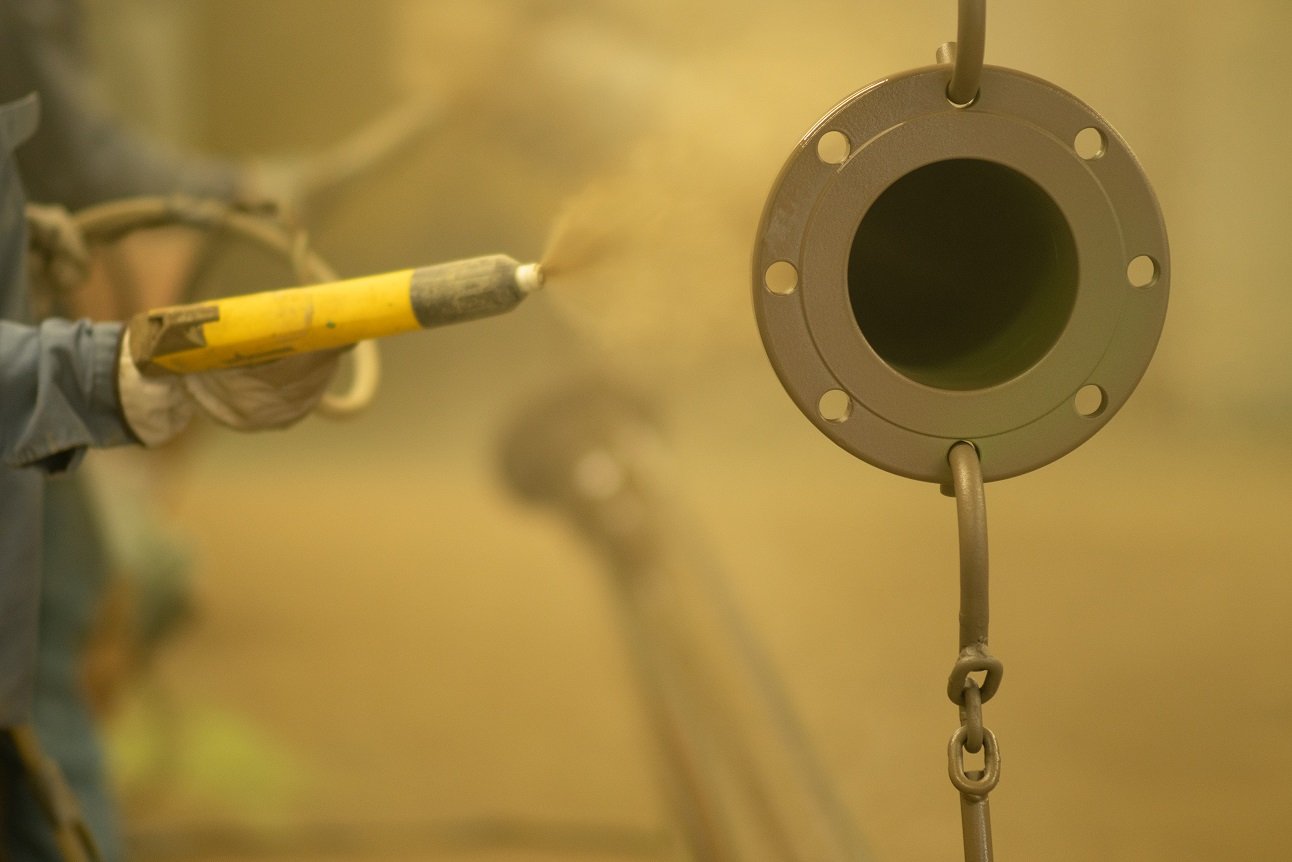

Dependable and cost effective, powder coating consists is mixture of finely ground particles of pigments and resins sprayed (normally electrostatically) to a surface. It is then heated and fused into a smooth coating. Our powder coating system, XTRA SHIELD™, consists of a zinc-rich epoxy primer and a topcoat of high quality polyester.

XTRA SHIELD™ is cured at 400 degrees Fahrenheit.

XTRA SHIELD™ coating is electrostatically applied.

Surfaces are blast cleaned or chemically pre-treated.

XTRA SHIELD™ is cured at 400 degrees Fahrenheit.

XTRA SHIELD™ coating is electrostatically applied.

Surfaces are blast cleaned or chemically pre-treated.

Fusion Bonded Epoxy (FBE) is an epoxy-based powder coating that is applied to pipe and steel to protect from corrosion. The powder is applied to the substrate, normally to about 400 degrees Fahrenheit, where the powder melts into a liquid form and becomes a solid coating by chemical cross-linking. This process is known as fusion bonding, and will greatly extend the life of your pipes.

Phenolic primer is applied, and the substrate is heated and coated.

Pipes are inspected, including holiday detection and thickness checks.

Pipes are prepared with internal grinding and blast cleaning

Phenolic primer is applied, and the substrate is heated and coated.

Pipes are inspected, including holiday detection and thickness checks.

Pipes are prepared with internal grinding and blast cleaning

You are welcome to contact us about any of our services. We welcome all of your comments and suggestions. Please enter your contact information, and one of our team members will get back with you as soon as possible.

Carbon Steel Coated

Stainless steel

Stainless steel can cost 3 to 6 times more than carbon steel coating. Carbon steel saves you money on both pipes and fittings.

On every single weld, stainless steel can cost 25% more that carbon steel. Reduce costs throughout production and in the future.

.jpg)

We’d love to treat you and your team to lunch and discuss the challenges of mitigating corrosion. We’ll give engineers, project managers, and project designers important knowledge of the coating process, allowing for better piping designs and material choices for project feasibility. Our team will give you a tour of our facility and help you find ways to improve your operation, protect your investments, and reduce your number of pipe failures. We look forward to answering all of your questions.

Queston Perry, Corporate Estimator/Business Development/ NACE (AMPP) Level II Certified – Responsible for Customer Relations and Pricing Quotes as well as being actively involved in our Business Development efforts. Queston is very knowledgeable in all aspects of our Coating Processes and Quality Control programs in both North Basin facilities.

Established in 1943, NACE International is the world’s leading authority on corrosion prevention. We employ three NACE-certified inspectors, showing they received the best training. They consistently hold our coatings to the highest standards.